Description and application

UZIN KE 2000 S is a powerful solvent-free and low-emission dispersion adhesive. This adhesive has a very short waiting time and at the same time a very long application time. The adhesive can be used for “semi-wet”, “dry” or “contact bonding”. UZIN KE 2000 S is especially suitable for bonding PVC and rubber coverings, but can also be used as a universal adhesive for all common floor coverings. For application on floor and wall, indoors. Solvent-free.

Main application area:

- Homogeneous and heterogeneous PVC/CV coverings in sheets and tiles

- Rubber in strips, e.g. noraplan up to 4 mm including acoustic or foam backed coverings Also applicable as universal adhesive for

- Carpets with conventional backings

- Smooth needle felted or woven carpets

- PVC/CV coverings, also PVC design coverings

Features/product benefits:

Due to the improved recipe and the latest raw material technology, many properties have been improved, so that the new adhesive has a wider field of application.

- Odor neutral during and after processing

- Very easy to blend

- Short waiting time

- Long waiting time

- GISCODE D 1 / Solvent Free

- EMICODE EC 1 PLUS / Very low-emission Plus

- RAL UZ 113 / Environmentally friendly (very low emission)

Extensive areas of application

As a special adhesive suitable for:

- Chlorine-free, elastic covering e.g. Upofloor LifeLine

- PU coatings in strips up to 2.0 mm, e.g. WPT PURLine

- Flotex

- Wall cladding, eg. PVC covering in wet areas As a universal adhesive also suitable for

- Carpets with all common backings including latex foam backings, felt fleece backings, etc.

- Corkment as well as suitable for various UZIN insulation mats and underlayers

Suitable on/for:

- absorbent, leveled substrates as wet or semi-wet bonding

- dense, non-absorbent substrates such as synthetic resin screed floors, UZIN KR 410 or on UZIN insulation mats as dry bonding

- dense, non-absorbent substrates as contact adhesive (only PVC/CV and rubber cover)

- heavy loads in residential, project and industrial applications, e.g. in hospitals, busy shopping centers, shops, etc.

- hot water underfloor heating

Processing UZIN KE 2000 S PVC and Rubber Glue

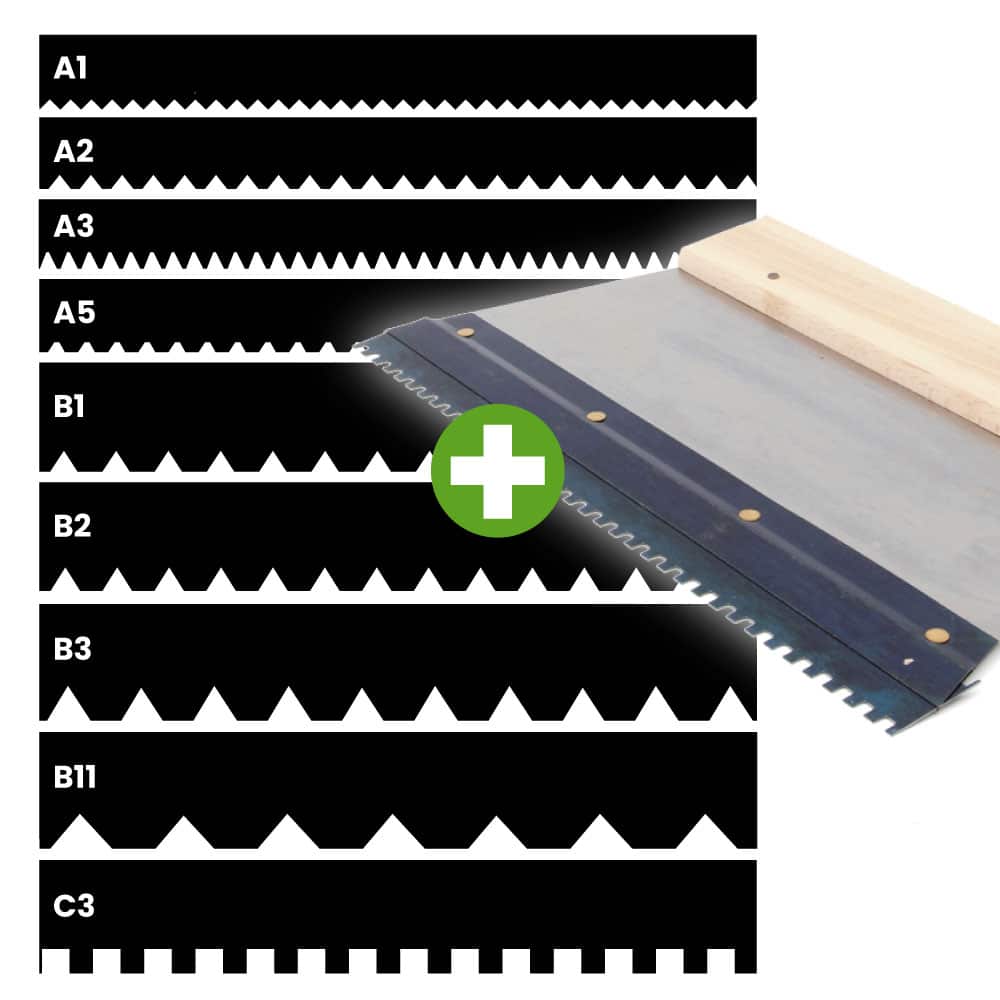

- Apply the adhesive evenly to the substrate using the correct sealant spreader (see sealant spreader/consumption in the product information sheet). Adhere to a waiting time that is appropriate to the application method, application amount, conditions, absorbency substrate and floor covering. Do not glue a larger surface than can be finished within the open time/laying time. For standard bonding on leveled substrates, only use the “wet” or “semi-wet” bonding.

- Insert the cover after a short waiting time, the adhesive bead must be pressed flat. Press on or roll on to make any raised areas heavier. Do not trap air under the cover. Let the whole rest for 20 minutes and then roll again and rub again at the seams and sides.

- Remove fresh glue stains immediately with water

Consumption Uzin KE 2000 S PVC Rubber Glue

The use differs based on the coarseness and smoothness of the substrate as well as the structure of the covering that is glued. The usage table per substrate/covering can be found in the product information sheet.

Reviews

There are no reviews yet.