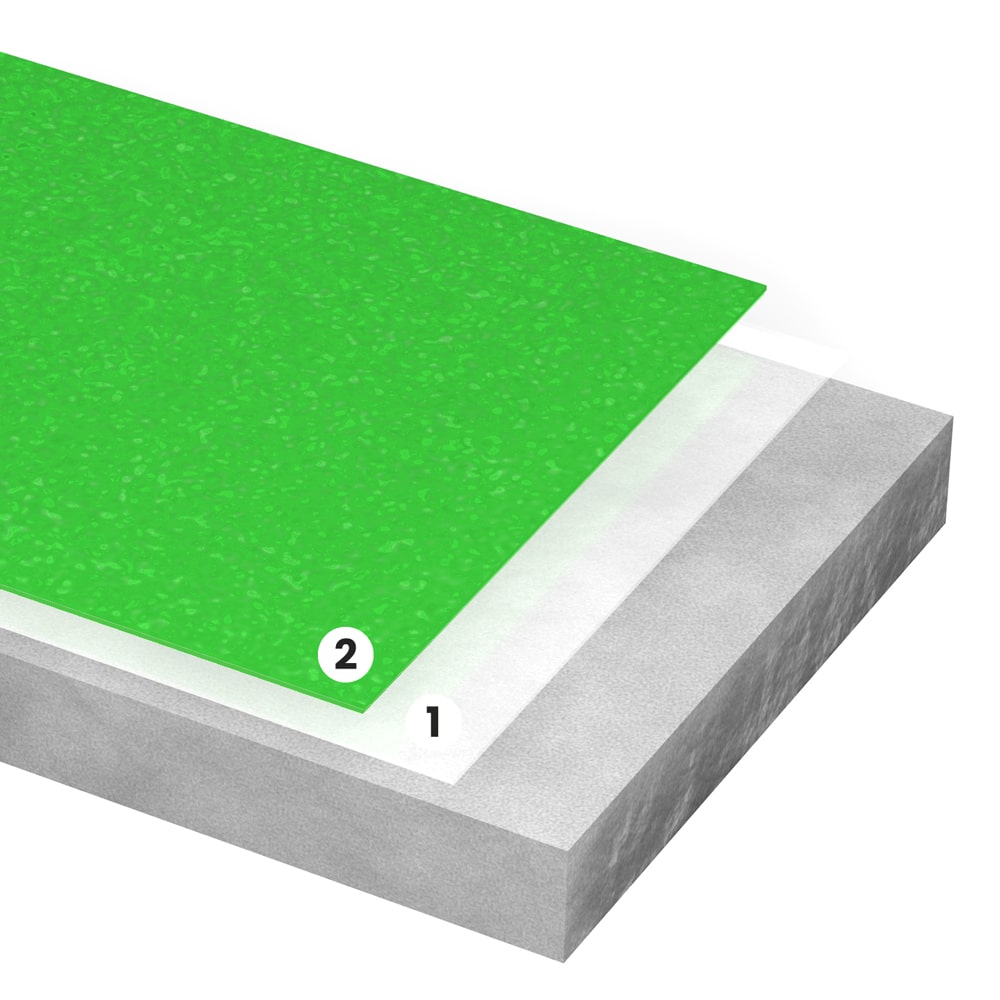

Dispersion primer for fast blocking of unheated cement screeds up to a maximum of 3 CM-%.

Main application area:

- PVC design flooring

- PVC and CV coverings in sheets

- Rubber coverings in sheets up to 10 mm thick (e.g. norament®)

- Rubber granulate coverings or underlays (e.g. Regupol®)

- Linoleum coverings in sheets up to 4 mm thick

- Artificial turf, outdoor and sports surfaces

- in combination with UZIN RR 185 and industrial flooring (e.g. Gerflor GTI®)

Suitable on/for:

- flat, absorbent and non-absorbent substrates

- deformable or elastic substrates (e.g. underlays, wood, metal)

- on hot water underfloor heating

- the stress with chair castors according to DIN EN 12 529

- the very high stress, e.g. in the commercial and industrial sector

- Suitable for wet, shampooing and spray extraction cleaning according to RAL 991 A2

Product advantages/features

UZIN KR 430 is a 2-component polyurethane adhesive for rubber and PVC coverings to be installed on dry substrates. The adhesive is ideal for highly stressed surfaces. For indoor and outdoor use.

- Shrinkage-free

- Flexible

- High resistance to heat and cold

Consumption

250 – 600 g/m2

Substrate preparation

The substrate must be sound, load-bearing, dry, free from cracks, clean and free from materials that would impair adhesion

(e.g. dirt, oil, grease). The surface must be thoroughly vacuumed, primed and filled with a high-strength cement putty. Suitable primers and fillers can be found in the UZIN product overview. If necessary, fill deformable substrates, such as mastic asphalt or underlays, with the 2-component PUR filler UZIN KR 410 and bond the corresponding top coat within 24 to 48 hours. Dense and smooth substrates must be degreased, sanded and primed if necessary. The substrate must be tested in accordance with applicable standards and concerns must be raised if there are any deficiencies. Allow the applied primer and filler to dry thoroughly.

The product data sheets of the products used must be observed.

Processing

- Allow container to come to room temperature before use and shake thoroughly.

- Apply the primer with the nylon plush roller evenly and generously to the substrate. Avoid puddling. For the first application, dilute the primer with 1:1 water. After approx. 1h drying time, apply the second coat undiluted and cross-coated.

- Clean tools with water after use.

Processing

Allow combination container to come to room temperature before use. Mix resin and hardener as described on the container. Ensure good mixing, especially in the bottom and wall areas of the container, as poorly mixed adhesive will not cure.

Apply the adhesive evenly to the substrate with a suitable notched trowel and allow to flash off, depending on the application quantity, room climate, substrate absorbency and type of covering. Only apply as much adhesive as can be applied to the reverse side of the covering within the open time with good wetting without the covering “floating”. Process adhesive quickly, observe pot life, avoid displacement.

After the short flash-off time, lay the coating, rub down and re-roll after approx. 2 hours.

Remove adhesive contamination when fresh with cleaning cloths from the UZIN Clean-Box. Adhesive contamination in the cured state can only be removed mechanically.

More product information

Under the heading Documents and Downloads you will find further product information and safety instructions. A product information sheet will be emailed to you in the order confirmation.

Tips and tricks?

Visit our YouTube page, here you will find all practical teaching videos.

Free color fan?

You can order a free* color guide to find the perfect color for your project.

Reviews

There are no reviews yet.